How much is ESD really costing you? This free tool tells you in under a minute

If your team is working without ESD-proof workstations, you may already be paying the price.

What’s the real cost of not using ESD workstations?

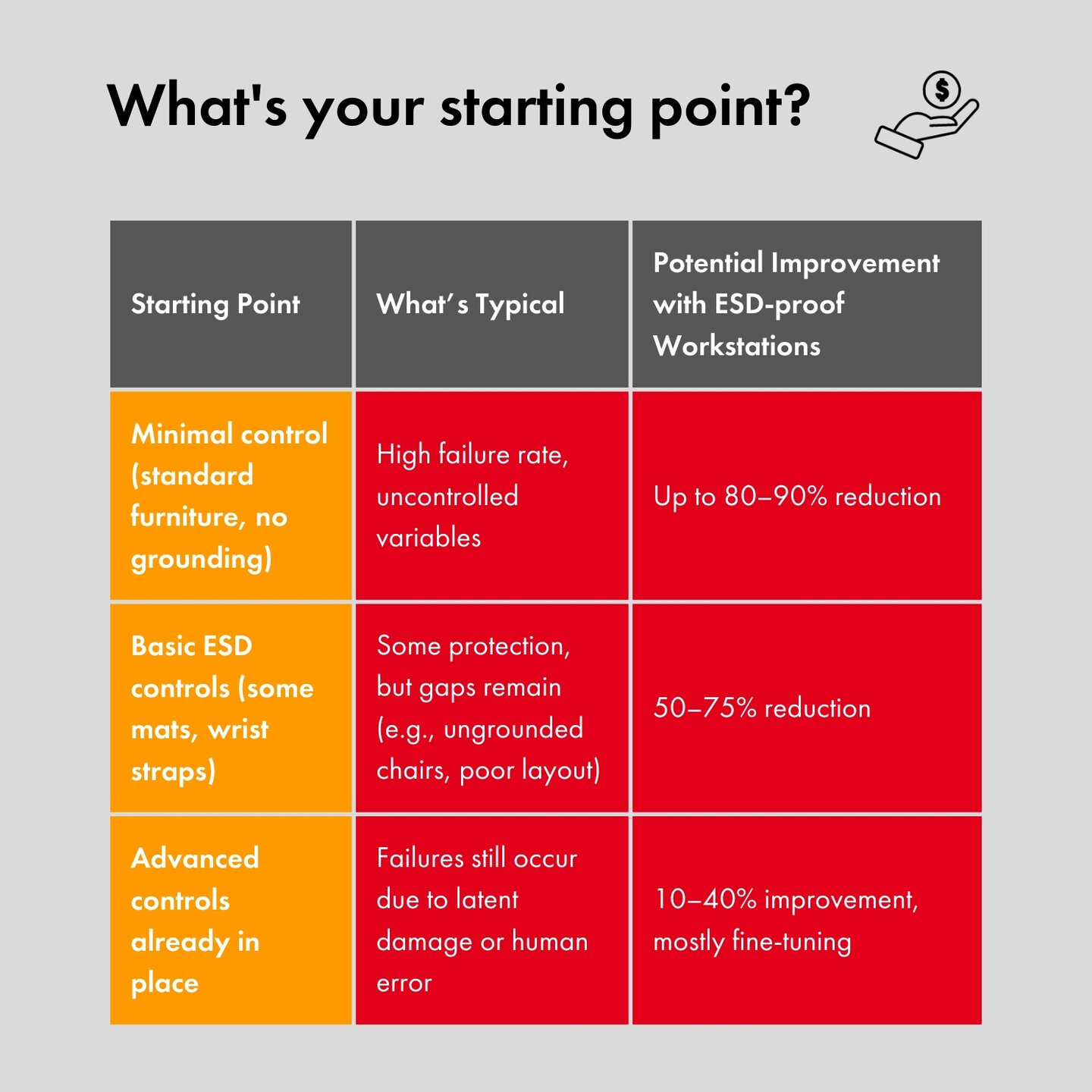

Industry experience and studies have shown that a significant portion of electronics failures can be attributed to electrostatic discharge (ESD) events — even in facilities that have some level of control in place.

Many of these failures are latent, only surfacing after the product has left your facility. This leads to:

- Field returns and warranty repairs

- Missed quality targets

- Unexplained customer dissatisfaction

Try the free ESD savings calculator

To help manufacturers estimate the financial impact of poor ESD control, we created the Treston ESD Savings Calculator.

Use the calculator now — it takes less than one minute.

Real-world examples of ESD costs and savings

Want to see what ESD failures might be costing your business? Here are three sample scenarios using realistic data from various industries:

Example 1: Mid-sized electronics manufacturer

- Annual production volume: 600,000

- Current ESD-related failure rate: 3%

- Cost per failed unit: $45

- Potential improvement with ESD-proof workstations: 60% reduction

- Estimated savings/year: $486,000

> A modest failure cost, but high production volume makes the savings significant. Even with basic ESD control in place, improving your workstations can reduce thousands of avoidable failures.

Example 2: High-value, low-volume manufacturer

(e.g. medical devices or aerospace)

- Annual production volume: 100,000

- Current ESD-related failure rate: 2%

- Cost per failed unit: $300

- Potential improvement with ESD-proof workstations: 60% reduction

- Estimated savings/year: $360,000

> Even with a relatively low failure rate, high-value products mean that each ESD-related failure is costly. An ESD-proof workstation pays off quickly.

Why ESD workstations matter in electronics manufacturing

An ESD workstation is much more than a grounded tabletop. It’s a fully integrated, standards-compliant system designed to shield sensitive components from electrostatic discharge throughout your production process.

Treston’s ESD-proof workstations are:

- Compliant with IEC 61340-5-1 and ANSI/ESD S20.20

- Modular and configurable to meet the demands of your specific production line

- Built for long-term reliability and consistent ESD protection

Try the free ESD savings calculator

To help manufacturers estimate the financial impact of poor ESD control, we created the Treston ESD Savings Calculator.

Use the calculator now — it takes less than one minute.